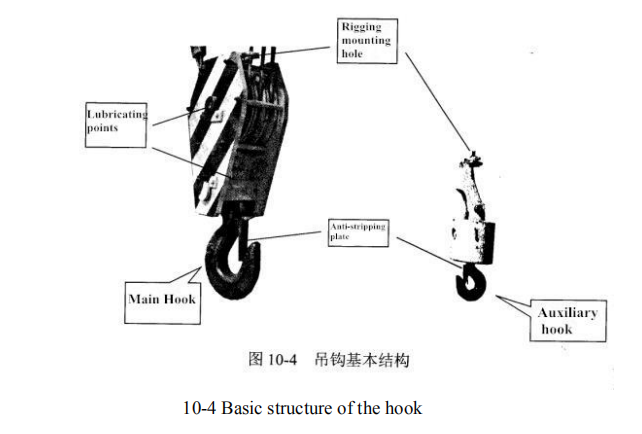

Basic Structure of Truck Crane Hook

The basic structure is shown in the chart 10-4.

Note:

The hooks should be lubricated regularly and lubricated at least every 100 hours. The dust proof cover should be removed when the auxiliary hook are lubricated.

Inspections:

When one of the following conditions occurs, the hook should be scrapped (the hook’s defects do not allow welding).

① Hook surface cracks or breaks.

② The degree of hook opening (see main and sub-hook signs) should not exceed 10% of the marked size.

③ Hazardous section wear up to 1% of original size.

④ The lanyard section wears more than 10% of the original height.

⑤ Hook torsional deformation more than 10%.

⑥ Hook tails and threaded parts and other dangerous sections and hooks have been deformed.

Boom tip pulley:

1. The boom pulley is composed of a bracket, a pulley shaft, and a shaft pin. When driving or when not in use, place it on the boom bracket.

2. When you need to use the arm-tip pulley to lift the heavy object, first install the arm-tip pulley on the head of the main arm, and bypass the arm winch pulley and install the auxiliary hook to use. At this time, the wire rope is singulated and can be raised and lowered quickly.

However, it should be noted that when using the boom pulley, reference should be made to the lift height characteristic curve of the main boom. The maximum lifting weight is: 0.5 ton.

3. When not use the boom pulley, you should put it back.