The Method of Installing the Wire Rope

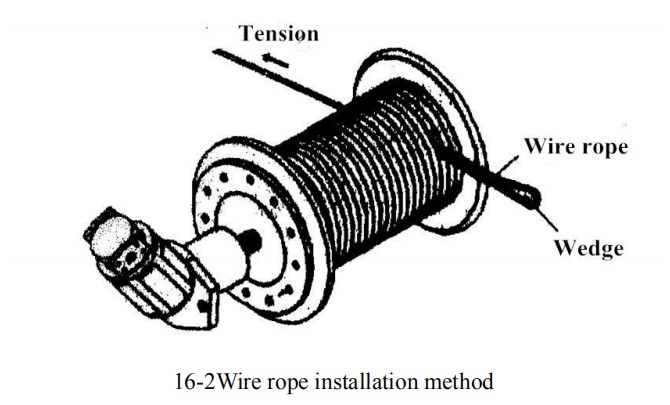

The method of installing the wire rope is shown in Figure 16-2

When winding the wire rope (main hoisting rope, secondary hoisting rope) around the crane reel, care should be taken to avoid twisting or kinking.

(1) Pass the rope end of the new wire rope through the top end of the boom.

When the main hoisting rope and the secondary hoisting rope are to be replaced, the secondary hoisting rope should be installed first.

(2)Pass the wire rope through the wire rope fixing hole of the reel, as shown in the figure above, then insert the rope end into the hole from the opposite side and install the wire rope on the reel.

At this time, the wire rope should be installed on the reel。

(3)Leave the length of the hook attached and slowly wind the rest of the wire rope around the drum.

In order to make the wire rope neatly wound on the drum, it is necessary to pull it tightly.

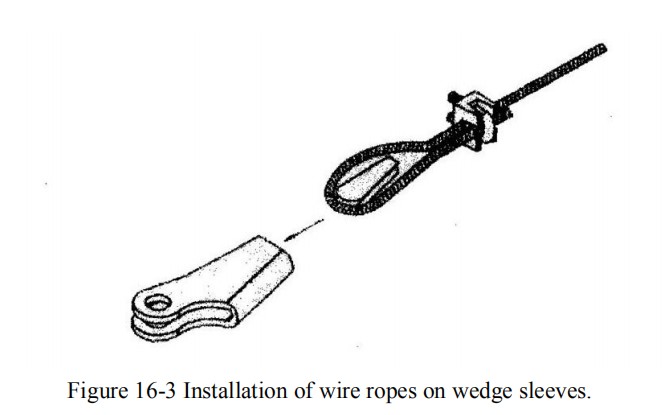

(4)Attach the hoisting rope to the rope end wedge cover, see Figure 16-3

Detachment of Wire Ropes

(1) Use a hand hammer and a round bar to open the wedge and remove the rope end wedge sleeve from the winding rope.

(2) Pull the wire rope outward from the drum and wind the wire rope neatly on the rope drum.

In the same manner as the removal of the rope-end inverted cone, the wedge is hit with a hammer and a round bar, and the wire rope is removed from the drum.

Precautions for Use of Wire Ropes

1 Remove the dirt on the wire rope regularly and lubricate it regularly for long-term use. If used interchangeably with spare wire ropes, it can extend the service life.

2 When using the new wire rope to extend the boom and perform work, sufficient care should be taken to avoid twisting the wire rope so as to avoid swinging the weight. When the wire rope is twisted, the wire rope is twisted without twisting by twisting the wire rope in the same direction as the twisting direction.

When loading a new wire rope, it is difficult to uniformly load the wire rope by rotating the reel for many times, so it is preferable to wind 3-4 turns at a time.

3 During the trial run, first lift the hook several times under no-load conditions, then lift and lift the lighter weight several times, and then gradually increase the load. In this way, the torsional hinge force will be dispersed and distortion will be reduced.

4 In order to use all wire ropes effectively, it is necessary to frequently replace the rope ends of the reels and hooks so that the wire ropes are uniformly worn.

Wire Rope Replacement Standards

a. With the increase of the use time of steel wire rope, the degree of its aging and scars will gradually become serious. The proper change of rope is judged by more men, but according to the rules for safety of vehicles such as cranes, the following items are stipulated.

1 When the wire rope breaks 10% per line (except for ropes);

2 When the diameter of the coke is more than 7% of the diameter;

3 When the wire rope has been knotted;

4 When the shape changes significantly, the rope is exposed, bird caged, corroded, etc.

When the above four phenomena occur, they must be replaced.

5 When the rope is pulled off the pulley and it is tensioned.

6 When the rope is damaged by heavy objects.

7 When the wire rope is damaged by electric welding or gas welding sparks.

8 When a short circuit occurs.

9 When it is affected by high heat.

The above phenomenon occurs, and it is judged according to the degree of replacement.

Apply grease on wire rope

1. Before applying the grease to the wire rope, use a brush, cloth, etc. to wipe off the dust and used wire rope grease attached to the surface of the wire rope.

2. Apply a wire rope grease evenly to the surface of the wire rope with a brush, cloth, or the like.

Because waste oil and mechanical oil are acidic, do not use it.

Note: When moving the wire rope by hand, in order to avoid the fingers being entangled with the wire rope, never touch the wire rope at the front of the pulley.