The Security System of Truck Crane

Security system:

In order to ensure safe and reliable operation of the crane, the crane is equipped with a relatively complete safety device, so that in the event of a situation other than the occurrence of protection, or to remind the operator attention, never played a role in security protection.

1. Overflow valve in hydraulic system.

The abnormal high pressure in the circuit can be suppressed to prevent damage to the hydraulic oil pump and motor and prevent the system from being overloaded.

2. Boom luffing mounting device.

When accidents occur and the high-pressure tubing in the hydraulic circuit of the boom hydraulic cylinder is damaged, the balance valve in the hydraulic circuit locks the hydraulic oil in the lower chamber of the variable-amplitude cylinder so that the boom does not fall, and the lifting operation is never ensured. safety.

3. Boom telescopic safety device.

When the accident happens, when the hydraulic circuit of the telescopic cylinder is damaged, the balance valve in the hydraulic circuit, that is, the hydraulic oil in the upper cavity of the lock expansion cylinder, will not retract by itself, thus ensuring the safety of the lifting operation.

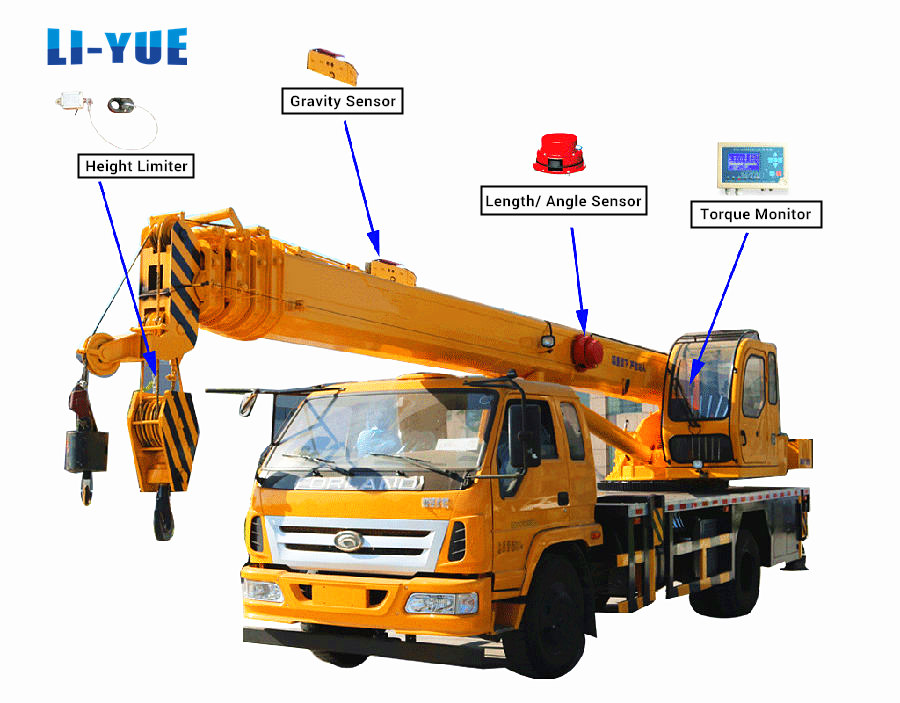

4. Height limiting device.

When the hoist exceeds the specified height, contact the limit weight hammer, turn on the stroke switch, alarm sound from the buzzer in the electric box, at the same time cut off the hoisting of the hoist, the extension of the boom, the operation of the arm falling down and so on, to ensure the safety.

At this time, only the hooks can be operated down, the boom retracts and the boom is lifted up, and the handle is operated in a safe direction, so that the limit weight hammer can be released from the constraint, and the operation can be restored to normal. In a special situation, if you still need to do a small lifting operation, you can press the forced button of the electric box.

At this time, the role of the limit will be relieved, all operation actions will return to normal. But the operation at this time must be very careful, in case of an accident.

5. Outrigger locking device.

When the high pressure tubing leading to the vertical oil cylinder of the leg is damaged, the bidirectional hydraulic lock in the hydraulic loop of the leg can block the pressure oil in the two chambers of the hydraulic cylinder of the leg, so that the leg will not retract or protrude, thus ensuring the safety of the lifting operation.

6. Angle indicator.

The boom angle indicator is arranged behind the basic arm (that is, the right side of the control room). The operator can clearly observe when sitting in the control room and can accurately indicate the elevation angle of the boom.

7. Lifting characteristics chart.

It is set on a manipulating interior wallboard that lists the rated weight and lift height for various arm lengths and various operating ranges. For operational review. When lifting, do not exceed the values specified in the table.